|

______________________________________________________________________________________

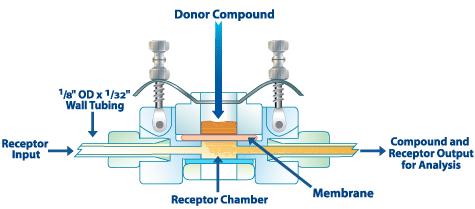

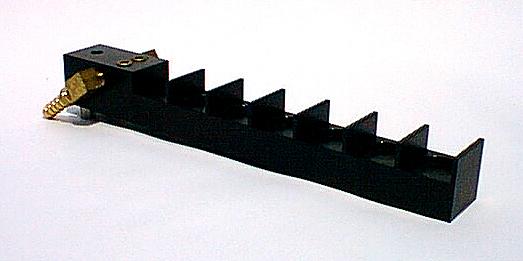

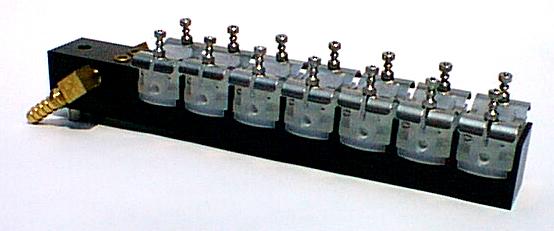

Pictured below is a cross-sectional view of an In-Line Cell with HPLC fittings and sections of inlet and outlet tubing included. The HPLC ports in standard In-Line Cells are threaded for standard 1/4"-28 connectors such as those sold by Upchurch Scientific. We also supply In-Line Cells with #10-32 threaded connections upon request. The In-Line Cell may be thought of as a flow type Franz Cell with a very small receptor volume. In-Line Cells locate the membrane of interest in the horizontal plane and have donor chambers open to the air although occluded donor chambers are available.

____________________________________________________________________________________

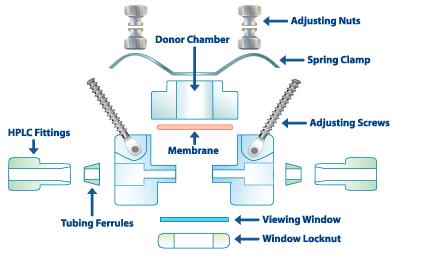

The drawing below is an exploded view of the In-Line Cell pictured above.

___________________________________________________________________________

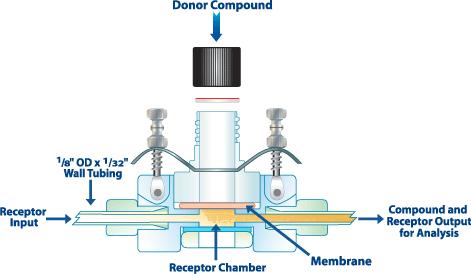

This drawing is of an In-Line Cell with a donor chamber having threads for a septum and cap. These cells may be used when the donor chamber needs to be occluded but may also be used without the septum and cap.

__________________________________________________________________________________

Series I In-Line Cells and Components - "xx" denotes orifice diameter.

- #1K001-XX In-Line Cell 3mm-12mm

- #1K001-XX-VD In-Line Cell w volatile compound donor compartment/clamp

- #1KM01-XX In-Line Cell 3mm-12mm with interchangeable membrane support

- #1KMM1-XX Squier In-Line Mucosal Cell

- #1K201-XX Dual-Flow In-Line Cell 3mm-12mm

Series I In-line Cell Extra Components - "xx" denotes orifice diameter.

- #1K012-XX Membrane Support

- #1K015-XX Donor Compartment/Clamp

- #1K016-XX Donor Compartment/Clamp Cap

- #1KS02-XX Volatile Compound Donor Compartment/Clamp

____________________________________________________________________________

In-Line Cells or Bronaugh cells?

The Bronaugh cell has input and output arms pressed into its teflon body. Over time these arms can become loose and leak. Teflon also has a cold flow property and during the attachment and detachment of the tubing element from the peristaltic pump, the arms are moved ever so slightly side to side and ultimately come loose. Our In-Line Cells use standard 1/4-28 HPLC fittings to attach the tubing to both ports of the receptor chamber.

The glass viewing port in the bottom of a Bronaugh cell is pressed in and cannot be removed without completely ruining the cell. The manufacturing processes used in making these 1/4" thick "glass beads" often make it difficult to see into the receptor chamber. Our In-Line cells use a 1/16" thick glass disc which is held in place by a locknut and a unique sealing ridge at the base of the receptor compartment. The underside of the membrane is easily seen and the window is handily removed for properly cleaning the cell.

The bodies of our In-Line cells are made of Kel-F or Neoflon, the same material the arms of the Bronaugh cells are made of. Kel-F is tough and servicable over the long term and has less adsorption problems than teflon, it also is moisture and radioactivity impermeable.

Our In-Line cells can be supplied with all kinds of different donor compartment and receptor compartment dimensions and volumes because we manufacture them ourselves. Our #1K001-9-C In-Line Cell has internal dimensions identical to Crown's popular TDC-01-9 Bronaugh cell if you already have data that has been gathered from them. Many times the inherent constraints of the Bronaugh cell design do not allow data to be gathered in the manner you want.

Our clamping mechanism is designed to allow the user to gently place the donor compartment on top of the membrane and clamp it with our unique clamping spring. The pressure of the spring is settable with setting and locking nuts and is uniform across the top of the donor compartment. The Bronaugh cell clamp nut is screwed down on top of the membrane with the usual rotary motion and as it contacts the membrane it may twist, deforms and occasionally tear it.

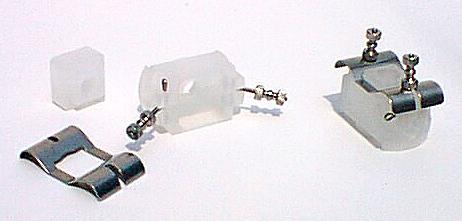

PermeGear In-Line Cell Assembly & Use

In-Line Cells come completely assembled and ready to use except for sterilizing. After use, it is recommended that they be disassembled and cleaned. They are re-assembled as follows: The body of the cell is held upside-down and the glass or polycarbonate viewing window is placed onto the sealing surface of the receptor compartment. The window locknut is screwed in snugly against the viewing window, overly tightening this locknut is not necessary. The cell is placed on a horizontal surface and each of the adjusting screw and pressure setting nut assemblies are replaced with the cotter pins that allow them to swivel in and out of the slots in the stainless steel spring. The membrane to be used is placed inside the cell over the orifice which is the top of the receptor compartment. The donor compartment is lowered down within its mating cavity until it rests on top of the membrane. The stainless steel clamping spring is lowered over the donor compartment onto the clamping surface. The adjusting screw assemblies are swiveled into place in the slots of the spring and the pressure setting and locking nuts are adjusted to the desired pressure. Connectors are installed with tubing into the 1/4-28 HPLC inlet and outlet ports and the cell is placed in a Cell Warmer or Twin-Flow Conversion System to be brought up to temperature.

In-Line Cell

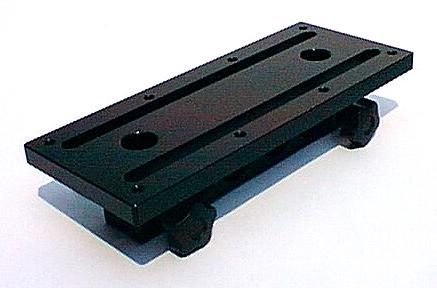

In-Line Cell Warmer

In-Line Cell Warmer

Cell Warmer Support

|